90 Degree Cpvc Elbow Product code:-3917

Product Details:

- Surface Finish Smooth

- Features Good Quality

- Material CPVC

- Technique Casting

- Size Standard

- Color White

- Click to View more

90 Degree Cpvc Elbow Product code:-3917 Price And Quantity

- 100 Piece

- 30.74 INR/Piece

90 Degree Cpvc Elbow Product code:-3917 Product Specifications

- CPVC

- Smooth

- White

- Casting

- Good Quality

- Standard

90 Degree Cpvc Elbow Product code:-3917 Trade Information

- 1 Piece Per Month

- 1 Week

Product Description

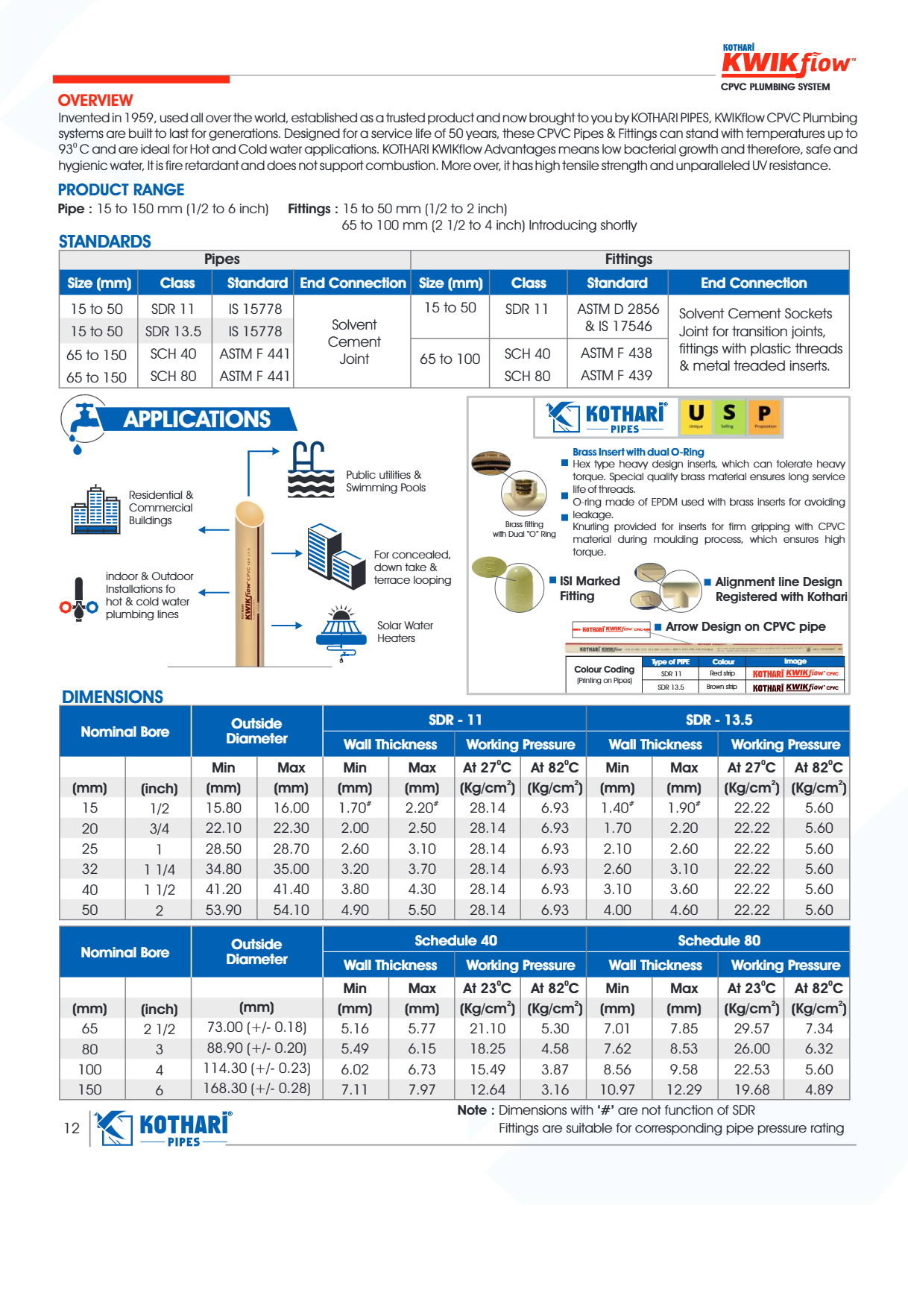

CUTTING Easily cut with a wheel type plastic pipe cutter or hacksaw blade Cutting pipe as squarely as possible provides optimal bonding area within a joint DEBURRING BEVELING Burrs and filings should be removed from the outside and inside of the pipe Debarking tool pocketknife or file are suitable for this FITTING PREPARATION The pipe should make contact with the socket wall from 1 3 to 2 3 often way into the fitting socket SOLVENT CEMENT APPLICATION Use only CPVC solvent cement or anal purpose solvent cement conforming to ASTMF493 otherwise it may result in joint failure ASSEMBLY Immediately insert the pipe into the fitting socket rotate the pipe 1 4 to 1 2 turn while inserting This motion ensures and even distribution of solvent cement within the joint SET AND CURE Curing time is shorter for drier environments smaller sizes and higher temperatures It requires 10 to 20 minutes for perfect joint

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+